We provide lifetime maintenance-free gear reducer motors, CCC/CE certification, support OEM/ODM manufacturer customization, stable product performance, small size, no noise, light weight.We devoted ourselves to lighting many years,covering most of Europe and the Vietnam market. We are expecting become your long term partner in china......

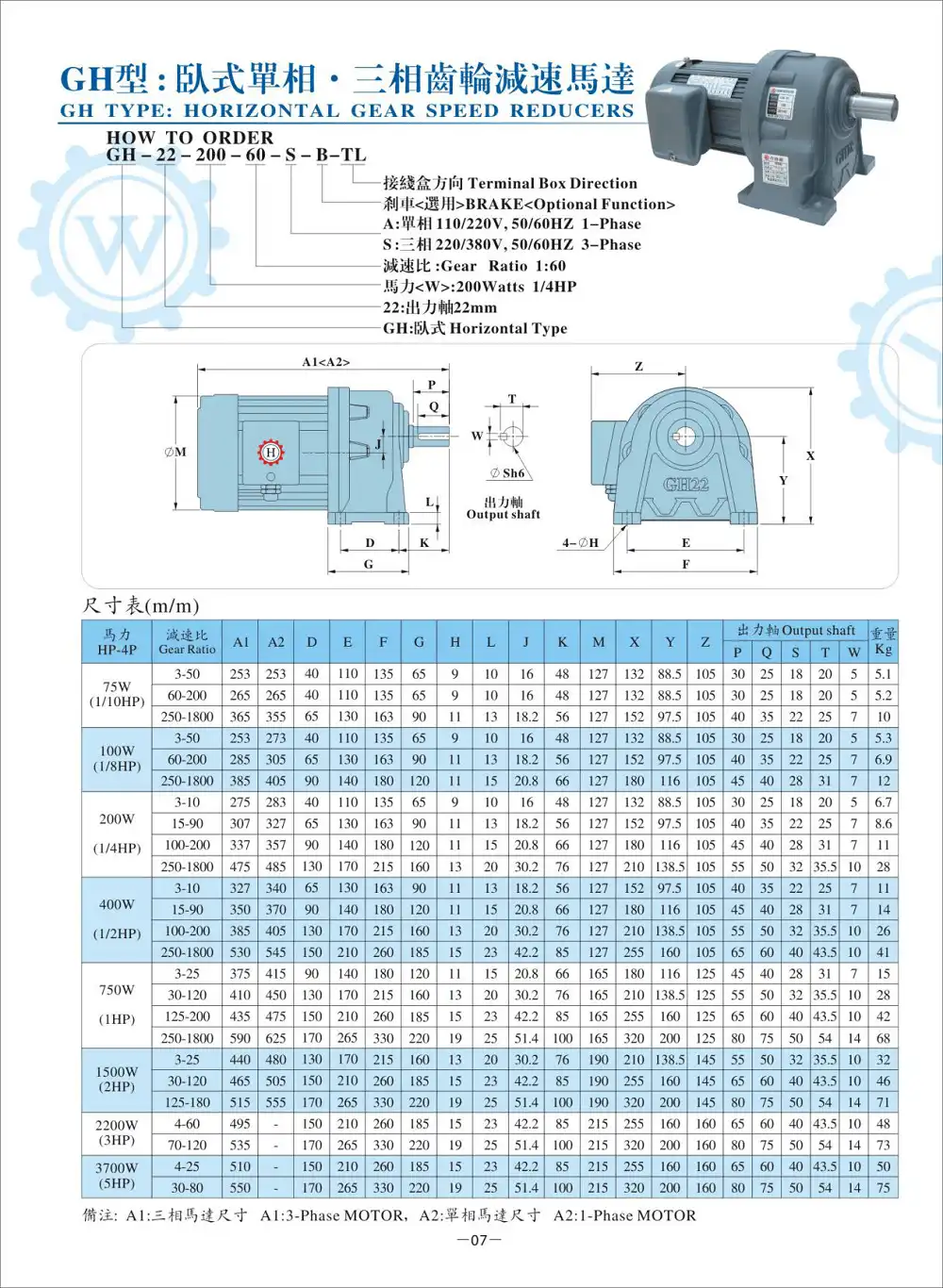

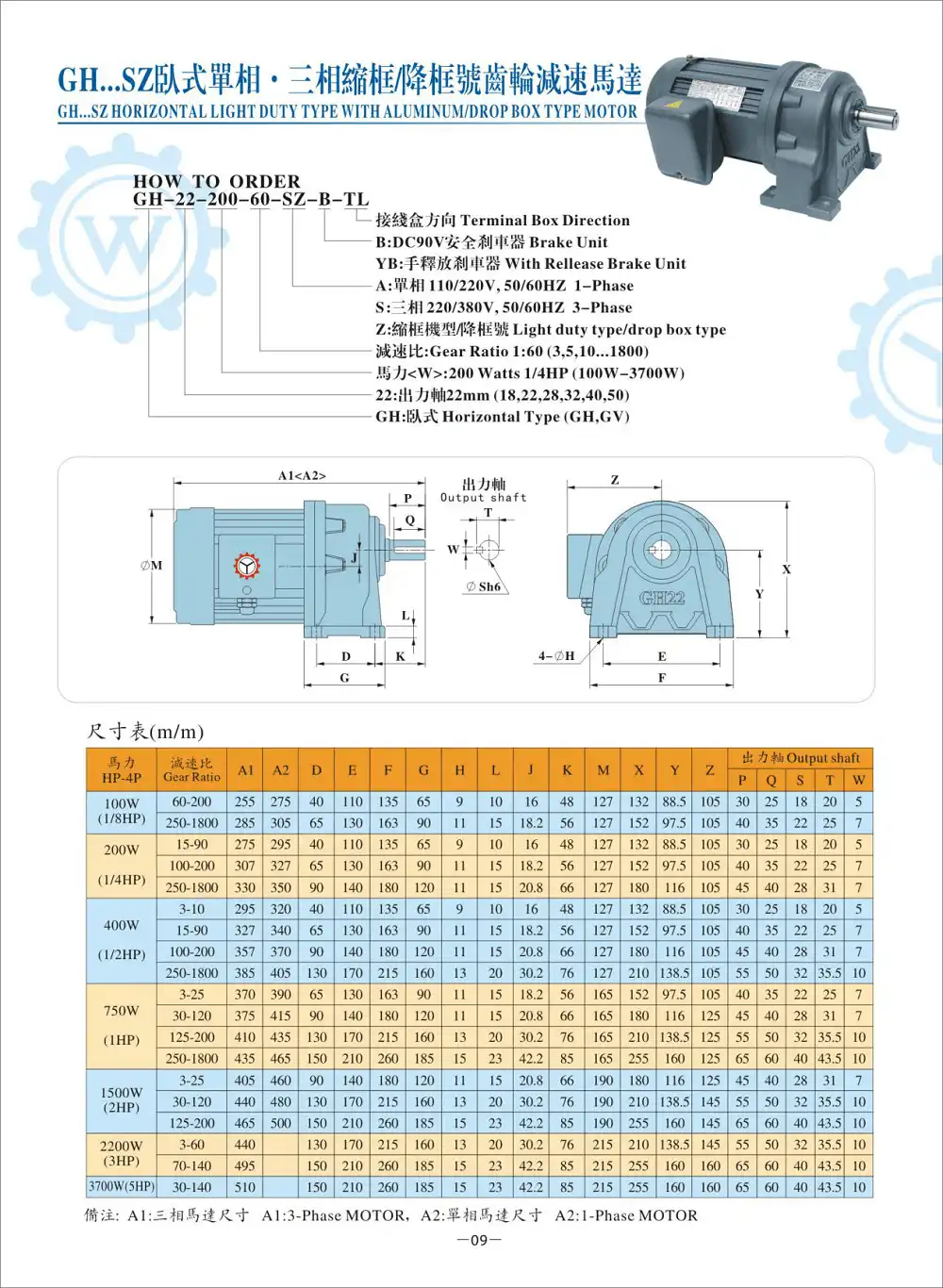

Geared motor selection parameters

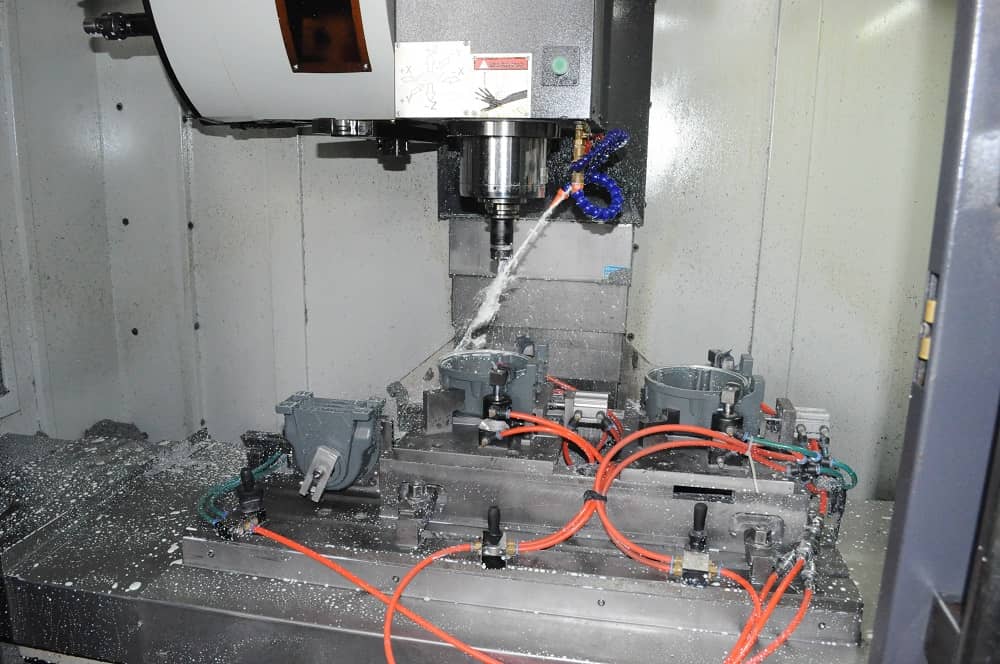

GH/GV medium gear reducer motor application field

Geared motor is an integrated body of reducer and motor (motor). This kind of integrated body is usually also called a gear reduction motor or a gear reduction motor. Geared motors are widely used in the steel industry, machinery industry, etc., generally through the combination of electric motors, internal combustion engines or other high-speed power equipment, through the combination of gears of different sizes inside the reduction motor to achieve the effect of torque increase and reduction.

Mainly used in: die-casting machinery, ultrasonic cleaning equipment, hardware machine tools, carton machinery, packaging and printing machinery, food machinery, conveying machinery, packaging pharmaceutical machinery, woodworking machinery; warehousing and logistics equipment, weighing equipment, transmission equipment, electronic machinery, power generation equipment, Textile printing and dyeing, three-dimensional parking, woodworking machinery, brewing machinery, beer machinery, automobile manufacturing and other automated machinery and equipment.

GH/GV medium gear reducer motor features

1. Compact structure, small size, beautiful appearance, strong overload capacity.

2. The transmission ratio is graded finely, the selection range is wide, the speed type spectrum is wide, and the special ratio can be customized.

3. Low energy consumption, superior performance, reducer efficiency as high as 95%, low vibration, no noise, maintenance-free.

4. The outer shell is powder-sprayed, anti-static, Taiwan imported gears, fine rolling and grinding, the gear shaft is carburized and heat treated, the surface is hard and internally tough, and has a long wear-resistant service life.

5. Adopt special lubricating grease of Taiwanese brand, high temperature resistance, noise reduction, computer high-speed precision stamping silicon steel sheet, good punching performance.

6. Using Taiwan Daya brand polyester imide enameled wire, high temperature resistance.

7. Adopting a new type of sealing device, good protection performance, strong adaptability to the environment, and can work continuously in harsh environments such as corrosion and humidity.

8. Both can be equipped with brake braking device, filled with liquid foam and packed in carton, safe and reliable.

9. The power is 75W-3700W, and the reduction ratio models are complete, which can meet the work needs of various automated machinery.

Features and performance of Taiwan Wanxin/Dongguan YUSIN general standard gear reducer motor:

| Time freeze: | continuous |

| Insulation class: | F-class insulation |

| Number of poles: | 4P (level 4) |

| Number of items: | three-phase AC motors, single-phase AC motors |

| Shell: | 18 axis-28 axis, aluminum alloy; 32 axis-50 axis cast iron |

| Gear material: | S45C (high frequency), SCM21 (carburizing), SCM4 (nitriding) |

| External structure: | three-phase, 0.1KW-3.7KW, fully closed external fan; single-phase, 0.1KW-0.2KW closed external fan, 0.4KW-1.5KW fully closed external fan |

| Surrounding environment: | avoid corrosive, explosive gas, water vapor environment, should be placed in a dry and well-ventilated environment |

| Applicable environment: | temperature -5 ℃-40 ℃; humidity above 85% |

| Altitude: | 1000 meters UNDER1000M |

| Junction box: | IP55 waterproof aluminum alloy junction box |

| Start mode: | three-phase, direct start; single-phase, 0.1-0.2KW capacitor operation, 0.4-1.5KW capacitor start operation |

| Standards: | International/National Standards IEC-34, CNS-10919ACCORDING TOIEC-34, CNS-10919 |

| Output revolutions (4P): | three-phase, 50HZ=1360~1430 revolutions; 60HZ=1640~1740 revolutions; single-phase, 50HZ=1340~1400 revolutions; 60HZ=1610~1720 revolutions |

Why choose us

1. Imported high-precision production and testing equipment: products through CCC, CE, CSA and many other authoritative certification, stable performance, safe and reliable.

2. Factory direct sale. Order can be loaded within 3 working days: Taiwan, Kunshan, Dongguan each set up factories, can be near the production of goods, 1 to 3 days can be received (except in individual regions).

3. Industry well-known brands, nearly 20 years of professional production experience: Taiwan-funded enterprises pearl river delta super 85% automatic machinery and equipment gear deceleration motor manufacturers.

4. All series of product models are complete, accept special customizable: all accessories warehouse management, a large number of spot, to meet the needs of assembly, maintenance at any time.

5. One-year warranty: the long warranty period is the presentation of our product quality, but also our direct commitment to cooperate with you.

6. Standby 24h

Products

Products