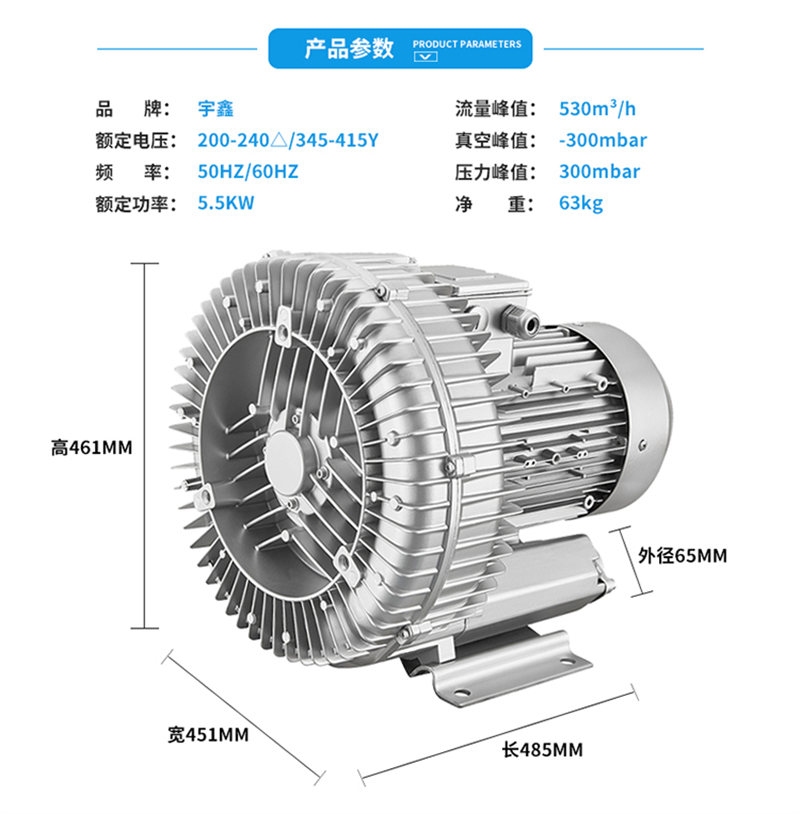

1. High pressure air blower of electric type

The electric type is powered by an electric motor, which is subdivided downward into mechanical type and hydraulic type.

The electric motor drives the crankshaft to make the plunger reciprocate, which directly pressurizes the material. Through multiple groups of plungers to provide continuous pressure, higher homogenization pressure, high output, but the minimum amount of material is larger, while the motor driven crankshaft requires a multi-stage reduction mechanism, so that the equipment efficiency is general and larger. Suitable for large-scale production.

Motor driven oil pump, through the hydraulic system to pressurize the material. Hydraulic system can provide higher pressure, higher equipment efficiency, relatively small volume, and the minimum amount of material is smaller. Can be applied to both test and production.

The material is pressurized by manual lever mechanism. Because of the manual pressurization, the capacity is lower, but it has the advantage of quick disassembly and assembly, and can be carried around, at the same time, the minimum amount of material required is very small, which is very suitable for small amount of test, and can fully meet the laboratory research and development needs.

Converts the pressure of compressed gas into hydraulic pressure. The equipment needs the support of nitrogen cylinder or compressed air machine, the consumption of gas is large, and the highest homogeneous pressure is generally low, but because there is no separate booster mechanism, so the volume is small, suitable for places equipped with air compressors