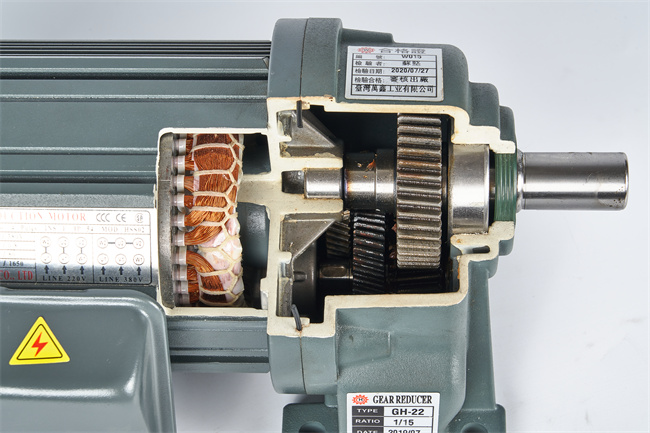

Gear motor is the motor and reducer of two independent incorporated in the mechanical integration definition names, also called a geared motor, gear motor, gear motor, gear is to use different number of teeth of n group, will be out of the shaft speed of the motor through the gear set down to the speed you need, and then by the output shaft output to the corresponding equipment. It is usually equipped with a 4-pole electric moto

Packaging machinery, casting machinery, food machinery, foaming machine, carton machine, machine, assembly line, transmission lines, logistics sorting lines, PCB circuit boards, cleaning machine, pipe bending machine, machine, folding machine, sewage treatment, animal husbandry and aquaculture, three-dimensional garage, washing machine, labeling machine, packing machine, lithium battery equipment, heaven and earth cover machine, environmental protection equipment, woodworking machinery, laser engraving, power lines Cable, hot glue machine, toy amusement equipment, reaction kettle stirring

Material aluminum alloy, pure copper wire good heat dissipation

Installation mode: horizontal, vertical

Layout: Output in the same direction

Deceleration ratio range: 1/3-1/6000 (special can be customized)

Purpose: Decelerate speed change, increase torque, enhance torque

Features: Maintenance free, helical gear impact resistance. No noise. Can add brake brake,

Power: 0.075 KW - 3.7 KW