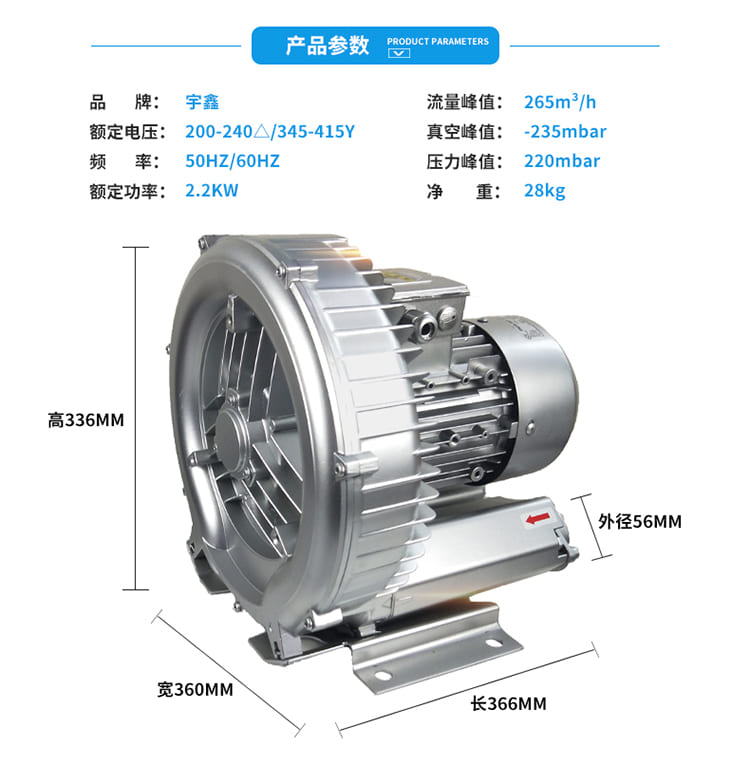

The use of high-pressure fan is good and bad, selection and maintenance is very important, the same product, if the selection is not correct, the use of a lot of problems, affecting the service life of high-pressure fan, serious is even direct damage to the high-pressure fan.

a, according to the calculated pressure and flow rate, the dry mortar production line on the curve to find the pressure and flow rate of the high-pressure blower at the same time to meet the working curve above the corresponding working point; then select the high-pressure blower model according to the working curve.

b, need to determine what function the site is using the high pressure blower, is it sucking or blowing, find the pressure-flow curve corresponding to the high pressure blower; if you look at the wrong curve, sometimes it will cause the selected product can not be used.

1、Maintenance of the air pump when the pressure or flow rate decreases

When there is a drop in pressure and flow, first cut off the power of the rotary air pump, check whether there is something blocking the air inlet, check the air inlet strainer, but do not remove the strainer, otherwise the debris will be sucked into the air pump, resulting in damage. Secondly, if you find that there is debris inside the machine, resulting in the rubber skin topped the solenoid, resulting in the solenoid can not restore the position. At this point you can open the shell of the vortex air pump, clean up the internal debris. Drill a small hole in the rubber skin to exclude the adsorption effect of negative pressure. The motor is out of phase or running in the wrong direction is also a cause of such failure, at this time should be checked and reconnected to the power supply, if the motor is burned, should be replaced with the same type of motor, single-phase motor to check whether the capacitor is intact, wiring is correct.

2, the maintenance of the air pump when the noise becomes large

First check whether there is debris in the vortex air pump pump body, if so, open the shell, clean up the internal debris; second check whether the impeller is stuck, at this time it is best to contact the manufacturer to repair, need to reassemble to eliminate the fault. The third check whether the bearing is damaged, replace the bearing if necessary.

3、Maintenance of the pump body when the temperature rises

First check whether the air inlet is blocked, clean the air inlet filter, but can not be removed, otherwise it will suck in debris damage to machinery and equipment. Please properly maintain the air pump gap when working. Secondly, check for debris in the body, open the shell and clean the internal debris.