I. Introduction of high speed motor

High-speed motor usually refers to the motor whose speed exceeds 10000 r / min. High-speed motors are small in size, can be directly connected to high-speed loads, eliminating the need for traditional mechanical speed increase devices, reducing system noise and improving system transmission efficiency. Currently, induction motors, permanent magnet motors and switched reluctance motors are the main ones that have successfully achieved high speed.

The main characteristics of high-speed motors are high rotor speed, high stator winding current and flux frequency in the core, high power density and loss density. These characteristics determine the high-speed motor has different from the normal speed motor unique key technology and design methods, design and manufacturing difficulties are often exponentially greater than the normal speed motor.

Applications of high-speed motors.

(1) High-speed motors are used in various applications such as centrifugal compressors for air conditioners or refrigerators.

(2) With the development of hybrid vehicles in the automotive industry, small size and light weight high-speed generators will be given full attention and have good application prospects in the fields of hybrid vehicles, aviation, ships, etc.

(3) High-speed generators driven by gas turbines are small in size and have high mobility, and can be used as a backup power source for some important facilities, or as an independent power source or small power station to make up for the lack of centralized power supply, which has important practical value.

Second, high-speed motor development status at home and abroad

1、High-speed induction motor

Induction motor rotor structure is simple, low rotational inertia, and can run for a long time at high temperature and high speed, so the induction motor is widely used in the high-speed field.

At present, domestic and foreign high-speed induction motor, the power of the largest 15MW, its speed of 20000 r / min, developed for ABB in 2002, using a solid rotor structure. High-speed induction motor speed is the largest developed by Westwind Air Bearings, speed of 300000 r/min, its power is 200 W, used for PCB drilling machine spindle. Similarly, a high-speed induction motor with a power of 10 kW and a speed of 180,000 r/min has been realized abroad for use as a test motor.

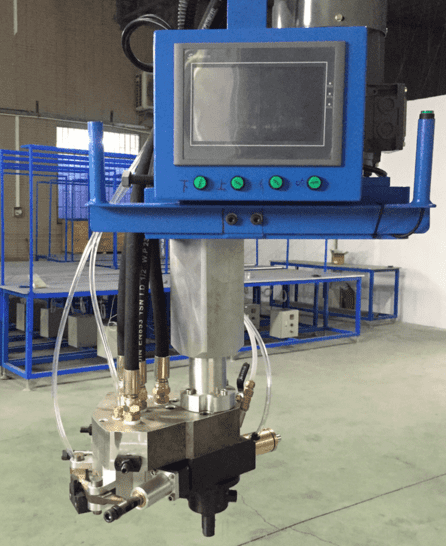

The picture below shows a high-speed induction motor developed by Westwind Air Bearings with a power of 200 W and a speed of 300,000 r/min.

Domestic research is relatively backward, among which Shenyang University of Technology, Chongqing Dema Electric, Naval Engineering University, Zhejiang University and other research units have carried out a lot of research work on high speed induction motors.

Chongqing Dema Motor has developed 100kW, 25000r/min high-speed induction motor. Shenyang University of Technology has conducted research on high-speed induction motors with 280kW power, 12000r/min speed, 132m/s linear speed and common laminated structure. The Naval Engineering University has conducted research on high-speed induction motors of 2.5 MW, etc.

2、High-speed permanent magnet motor

Permanent magnet motors are popular in high-speed applications due to their high efficiency, high power factor and large speed range. Compared with the outer rotor permanent magnet motor, the inner rotor permanent magnet motor has the advantages of small rotor radius and high reliability, becoming the first choice for high-speed motors.

At present, among the high-speed permanent magnet motors at home and abroad, the most powerful high-speed permanent magnet motor is researched in the United States, with a power of 8MW and a speed of 15000r/min. It is a face-mounted permanent magnet rotor with a carbon fiber protective sleeve and a cooling system that uses a combination of air-cooled and water-cooled for high-speed motors matched with gas turbines.

The Swiss ETH Zurich designed the highest speed high speed permanent magnet motor. The parameters are 500000 r/min, power is 1kW, linear speed is 261m/s, and alloy protective jacket is used.

Domestic research on high-speed permanent magnet motor is mainly concentrated in Zhejiang University, Shenyang University of Technology, Harbin Institute of Technology, Harbin Institute of Technology, Xi'an Jiaotong University, Nanjing Aerospace Motor, Southeast University, Beijing University of Aeronautics and Astronautics, Jiangsu University, Beijing Jiaotong University, Guangdong University of Technology, CSR Zhuzhou Motor Co.

They have carried out research on the design characteristics, loss characteristics, rotor strength and stiffness calculation, as well as cooling system design and temperature rise calculation of high-speed motors, and have produced high-speed prototypes of different power classes and speeds.

3、Switching reluctance motor

Switched reluctance motors are attracting attention for their simple structure, robustness, low cost and high temperature resistance, and are increasingly used in high-speed applications.

The maximum power of high-speed switched reluctance motor is 250kW and the speed is 22000r/min, and the maximum speed is 200000r/min and the power is 1kW.

Nanjing University of Aeronautics and Astronautics, Beijing Jiaotong University and Huazhong University of Science and Technology have carried out research work on high-speed switched reluctance motors, among which Nanjing University of Aeronautics and Astronautics has developed a 1 kW, 130,000 r / min switched

The main research and development directions of high-speed motors are.

Research on key issues of high power high-speed motor and ultra-high speed high-speed motor; coupled design based on multi-physical field and multi-discipline; theoretical research and experimental verification of stator-rotor loss; development and application of new materials such as permanent magnet materials with high strength and high temperature resistance, fiber materials with high thermal conductivity; research on high-strength rotor laminated materials and structure; application of high-speed bearings under different power and speed levels; good heat dissipation Design of high speed motor control system; Development of new rotor processing and assembly technology to meet the industrialization requirements, etc.