In the field of mechanical power, the motor is an important driving component, and its performance and characteristics affect the operation of the whole system to a great extent. Decelerating motor and ordinary motor are two common types, they have significant differences in structural design, output characteristics and so on. This article will explore these differences in depth and analyze their advantages and disadvantages in different application scenarios.

The ordinary motor is usually composed of the motor body and the output shaft, while the reducer motor is attached with a reduction device, that is, a gear box or other form of transmission mechanism connected to the motor shaft. This additional reduction device reduces the speed of the output shaft and provides greater output torque. Therefore, the deceleration motor has advantages in the application scenario of low speed and high torque.

The output characteristics of the motor and the ordinary motor are also different, the output speed and torque of the ordinary motor are basically constant, and change with the input voltage, while the output speed of the motor is reduced through the role of the deceleration device, and the output torque is increased to meet the needs of high load and low speed operation.

Ordinary motor usually has a high speed, and the speed is fixed, if you need to accurately adjust the speed, may need other accessories such as frequency converter to achieve. The gear motor, through the gear reduction device, can reduce the input speed to the required range, providing more speed options.

The structure of the ordinary motor is relatively simple, mainly composed of stator, rotor, bearing and so on. The manufacturing process is also relatively mature and the cost is low. The deceleration motor needs to consider more structural factors, such as the design, manufacturing and assembly of the reducer, and the manufacturing process is relatively complex and the cost is high.

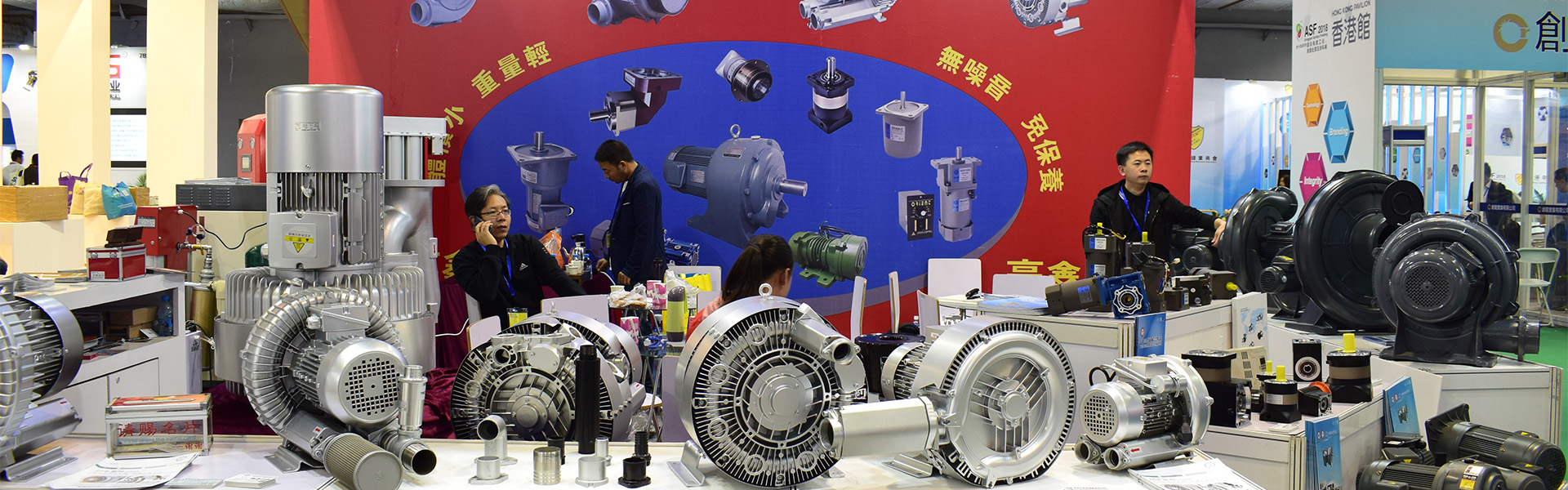

In the industrial field, ordinary motors are widely used in various mechanical equipment, such as pumps, fans, mixers, etc. Due to its advantages of fast speed, small size and light weight, ordinary motors have high efficiency and reliability in industrial applications. The deceleration motor is suitable for equipment that requires low speed and high torque drive, such as heavy machinery and metallurgical equipment. By using a decelerating motor, the operating speed of the equipment can be reduced and the output torque can be increased, thus improving production efficiency and product quality.

The differences between decelerating motor and ordinary motor are discussed, and their advantages and disadvantages in different application scenarios are analyzed. By comparing and analyzing the differences in operating principle, dynamic characteristics, circuit control mode, structural characteristics and manufacturing process, as well as the analysis of specific application cases, we can draw the following conclusions:

1. Ordinary motor has the advantages of fast speed, small size, light weight, etc., suitable for high-speed and efficient power needs; The decelerating motor is suitable for low speed and high torque application scenarios;

In industrial applications, ordinary motors are suitable for driving high-speed pumps, fans and other equipment; The deceleration motor is suitable for heavy machinery, metallurgy.