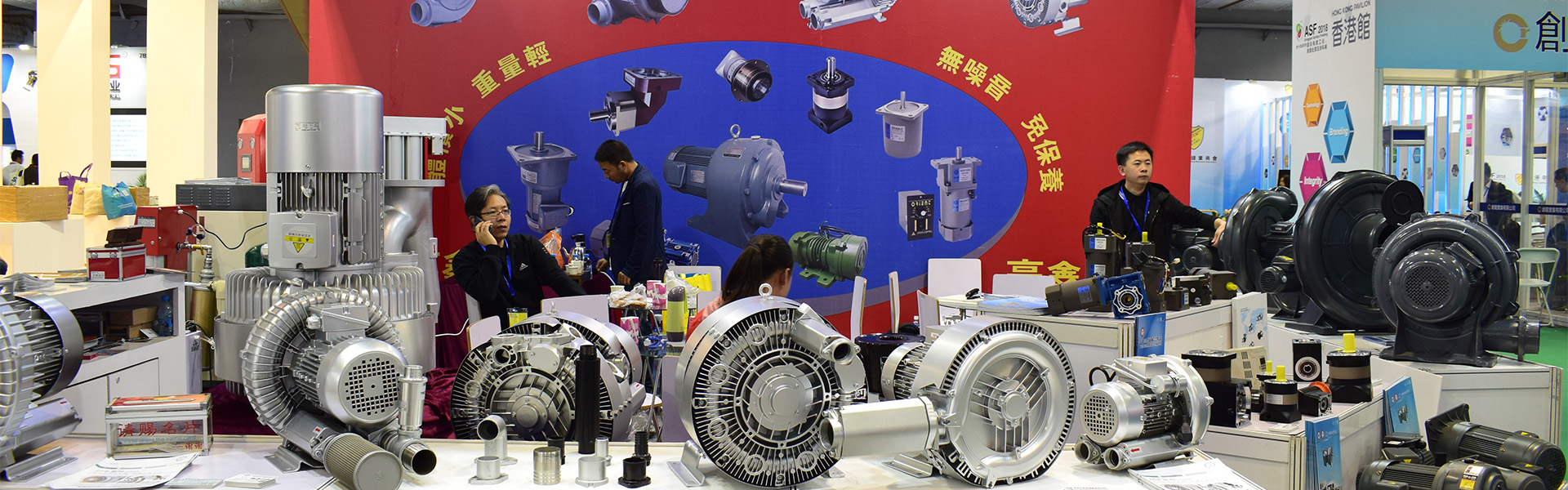

From the literal meaning, we can see that the former is like an electric motor, while the latter is like a gearbox. Gear reduction motor, also known as gear reduction motor, is a combination of gearbox and motor, both of which are modular combinations. The commonly used motors for ordinary motors are 4-pole (output synchronous speed 1500rpm), 6-pole (output synchronous speed 1000rpm), and 8-pole (output synchronous speed 750rpm). Among them, 4-pole motors are the most commonly used, and the higher the number of poles, the more expensive the price. Due to the fact that the speed used in the equipment is generally small, and the output speed or torque of the motor cannot meet the actual requirements, the speed of the motor is reduced through gear mechanism or other mechanisms (such as cycloid), and the output torque is increased to meet the actual speed and torque needs.

We know that an electric motor refers to an electromagnetic device that converts or transfers electrical energy based on the law of electromagnetic induction. Electric motors, also known as electric motors, are represented by the letter "M" (formerly known as "D") in circuits. Its main function is to generate driving torque as a power source for electrical appliances or various machinery. The generator is represented by the letter "G" in the circuit. Its main function is to convert mechanical energy into electrical energy. Currently, the most commonly used method is to use thermal energy, water energy, etc. to drive the rotor of a generator to generate electricity.

And the reducer is a power transmission mechanism that uses the speed converter of gears to reduce the rotation of the reducer motor to the desired rotation and obtain a larger torque.

Gear reduction motor is an abbreviation for the combination of motor and reducer, which is an integrated body of reducer and motor. As the name suggests, gear reduction is the use of n sets of gears with different numbers of teeth to reduce the output shaft speed of the motor to the speed you need. Gear reduction motor can be used in conjunction with rotary encoders.